Energiekonzepte & Planung

Would you be interested in increasing the efficiency of your operations simply by planning your facilities?

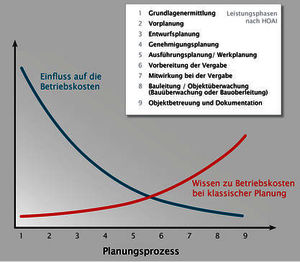

Each time a new machine is purchased or an old machine is upgraded, no matter whether it is for production plants, manufacturing resources, or technical equipment, energy and energy efficiency play a key role. Our customers' experience has shown that functionality, budget, and schedules are typically the main factors considered in the planning process. Efficient operations and the costs involved throughout the entire life cycle are rarely given a thought. But the results of the planning phase are critical for ensuring efficient operations and keeping costs to a minimum.

Our project experience has shown that simulations conducted early on can provide a much higher level of planning reliability. The simulation allows for the degree of energy efficiency to be significantly influenced at an early stage.

How an energy planner can help you

An energy planner assumes responsibility for the overarching coordination between production and building techology as well as energy supply. He or she also ensures consistency from the idea to the technical concept and realization, thus reducing high investment costs and errors.

In order to meet future demands, it is necessary to rethink planning. Similar to lean production, in which a cost-optimized plant is built tailored to the specific operations, this notion must also be applied to the field of energy. In logistics, large buffers were used to guarantee the productivity of individual units, though this concealed errors and increased the working capital instead of reducing total costs. Today, a lean and flexible production is key. With regard to energy, this task still lies ahead.